Clamps

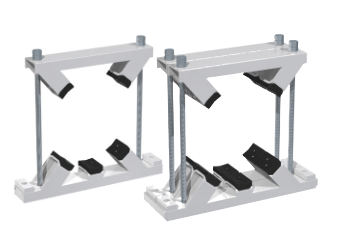

Standard and Heavy Duty Clamps

Standard and heavy-duty clamps give strong, reliable support in hydraulic, industrial, and mechanical systems. They secure pipes, hoses, and other components with precise positioning and firm stability. By holding lines in place, these clamps reduce vibration, prevent movement, and stop premature wear from friction or misalignment. Their strong materials and solid design help them perform well in high-pressure or continuous-use environments.

Standard clamps suit general industrial work. They stabilise hydraulic pipes, pneumatic lines, and tubing in manufacturing, agriculture, and mobile equipment. Heavy-duty clamps use reinforced bodies and stronger hardware for harsher conditions. They handle extreme vibration, dynamic loads, and high temperatures found in mining, construction, and large processing plants.

Both types come in many sizes, materials, and mounting options. This flexibility makes it easy to match them with a wide range of system layouts. When installed correctly, they improve reliability and increase operator safety. They also cut maintenance downtime by keeping components aligned and protected.

Standard and heavy-duty clamps form a key part of efficient industrial systems. They offer strength, consistent performance, and long-term peace of mind.

Catalogues

Special Clamps

Special clamps meet specific application needs that standard or heavy-duty clamps cannot handle. They suit unique geometries, specialised mounting points, and tough operating environments. These clamps give precise alignment, strong grip, and stable support across complex hydraulic and industrial systems. Their purpose-built design also helps when components need custom spacing, better vibration control, or non-standard pipe and hose sizes.

Many industries rely on special clamps. Mining, manufacturing, agriculture, construction, marine, and mobile equipment often use them when off-the-shelf options do not work. These clamps may include reinforced bodies, unique mounting bases, vibration-damping inserts, corrosion-resistant materials, or custom shapes. These features help them follow non-standard line routes and match exact system layouts. As a result, they reduce stress on hydraulic lines, prevent early wear, and protect connected components.

Special clamps also support environments that demand high safety and accuracy. Their custom fit keeps components secure under extreme pressure, rapid temperature changes, or constant vibration. This tailored approach creates smoother operation, lower maintenance needs, and longer equipment life. In systems where a standard clamp fails to perform, a special clamp offers a reliable, purpose-built solution.

Catalogues

Light Series

Light series clamps suit hydraulic and industrial applications where low weight, compact size, and precise positioning matter. They give reliable support without adding bulk and offer a strong yet lightweight way to secure pipes, hoses, and tubing. These work well in systems that do not need heavy-duty load capacity. Their streamlined design makes them ideal for mobile machinery, automation equipment, and compact hydraulic assemblies.

Even with their lighter build, light series clamps deliver solid grip and stability. They limit vibration, misalignment, and abrasion by holding lines firmly in place. Many options include vibration-damping inserts, corrosion-resistant materials, and durable mounting hardware. These features extend service life and protect system integrity under moderate pressures.

Light series clamps perform well in precision setups where accurate routing is essential. By reducing weight while still securing components, they improve equipment efficiency and simplify installation. They also lower mechanical strain on connected parts.

These clamps offer a dependable and cost-effective choice for systems that need precision, space savings, and low mass. They maintain strong performance without sacrificing grip or stability.

Catalogues

Saddle Clamps

Saddle clamps give secure and stable support for pipes, hoses, and cables. They anchor each line firmly and keep proper alignment. Their U-shaped design wraps evenly around the component and spreads pressure across a wide surface. This reduces pinching, deformation, and abrasion. As a result, saddle clamps offer a reliable option for protecting lines that need long service life. Installers usually attach them with bolts or threaded fasteners, which creates a rigid hold that resists movement and vibration.

Many industries use saddle clamps because they are simple, strong, and easy to install. Plumbing, electrical, HVAC, automotive, and industrial systems rely on them for neat and secure routing. These clamps work well when straight-line paths must stay accurate or when multiple lines need organised support. Manufacturers produce them in stainless steel, galvanised steel, and durable plastics to suit different environments and load requirements.

Saddle clamps reduce mechanical stress and help pipes and cables last longer. They also improve overall system reliability by keeping components stable. Their strong design and wide versatility make them a cost-effective solution for securing linear components across many applications.

Catalogues

U-Bolt Clamps

U-bolt clamps are versatile, durable fasteners that hold pipes, conduits, cables, and structural parts in place. Their “U” shape includes two threaded legs and a crosspiece, usually a plate or saddle. These parts work together to spread pressure evenly around the object. When you tighten the clamp, it creates a strong, uniform grip that stops movement, vibration, and misalignment. This makes U-bolts a reliable choice for both static and dynamic systems.

Many industries rely on U-bolt clamps for their strength and flexibility. You will find them in industrial, mechanical, plumbing, automotive, and construction settings. Their heavy-duty design handles high loads, harsh conditions, and constant vibration. Because of this, they work well for pipework, exhaust systems, machinery mounting, and structural bracing. You can also use them as anchor points for lifting, suspension, or support setups.

Manufacturers produce U-bolt clamps in stainless steel, galvanised steel, and durable alloy materials. These options offer strong corrosion resistance and long service life. Their simple installation and secure fastening help protect components, maintain alignment, and support safe operation across many applications.

Catalogues

Metal Clamps

Metal clamps use high-strength materials like stainless steel, carbon steel, and aluminium to deliver secure and durable fastening. Their rigid structure creates a firm grip on pipes, hoses, cables, and structural components. This grip holds steady under vibration, high pressure, and tough operating conditions. By stopping movement and misalignment, metal clamps help prevent premature wear and protect the overall system.

These clamps resist deformation and mechanical fatigue, which makes them ideal for heavy-duty applications. You will find them in hydraulic systems, heavy machinery, automotive assemblies, marine equipment, mining sites, and processing plants. The chosen material can add extra benefits, such as corrosion resistance, high-temperature capability, or increased load capacity.

Metal clamps come in many configurations, including U-bolts, saddle clamps, heavy-duty clamps, and specialised shapes. This variety makes it easy to match the clamp to the exact installation needs and environmental conditions. Their strong build and consistent performance offer long-lasting fastening in demanding industries. They give systems the stability and confidence required for safe and reliable operation.

Catalogues

Construction Series

Construction series clamps meet the tough demands of the construction industry. Equipment in this sector faces heavy loads, constant vibration, and harsh conditions, so the clamps need strong materials and reinforced designs. They give dependable support for pipes, hoses, and hydraulic lines on machinery such as excavators, loaders, cranes, and drilling rigs. Their robust build keeps components secure and prevents movement, abrasion, and misalignment during high-impact work.

These clamps suit applications where reliability and durability are essential. They stay stable under extreme pressure changes, sudden load shifts, and rough terrain. This stability protects hoses and other components from early wear or failure. Many construction series clamps also include vibration-damping inserts, corrosion-resistant coatings, and heavy-duty mounting hardware. These features extend service life and reduce maintenance needs.

Construction sites create unpredictable stresses and shifting angles, so the clamps hold components firmly while still allowing efficient installation and easy access. By keeping hose routing correct and providing solid structural support, they improve equipment safety and boost hydraulic performance.

In demanding environments where standard clamps fall short, construction series clamps deliver a long-lasting and reliable solution. They help machinery operate at its best, even under the toughest conditions.

Catalogues